About

Paper cup recycling challenge

Disposable paper cups are part of daily life across the world, enabling a convenient and safe way to enjoy our refreshing drinks wherever we are and while being “on-the-go”. Being made of up to 95% virgin fibre coming from sustainably managed forests, they are easily recyclable, but in practice the overwhelming majority of used cups are discarded in general waste meaning future recycling opportunities are restricted and uncertain.

Our solution: The Cup Collective

The Cup Collective provides a solution to this issue by accelerating paper cup recycling across Europe at an industrial scale. Our goal is to see the recycling of paper cups surpass a minimum of 5,000 tonnes in the coming years, while making it easier for consumers and businesses to contribute.

An at-scale solution

We are removing barriers to accelerate industrial scale solutions for paper cup recycling across Europe.

Realising commercial value

The Cup Collective

maximizes paper cup value through reusing cups as raw materials for recycling.

Delivering systemic change through partnership

The Cup Collective delivers an industry solution to a global challenge. We work with our partners through the value chain to put systems in place driving at-scale recycling of single use paper cups.

Every cup counts

The Cup Collective believes in the value of every single use paper cup. We are developing transparent and traceable solutions to regenerate the value of each cup for new uses.

Making it easy, making it the everyday

Creating a movement starts one cup at a time. By making it easy for consumers to do the right thing, we will ensure that no cup is left behind.

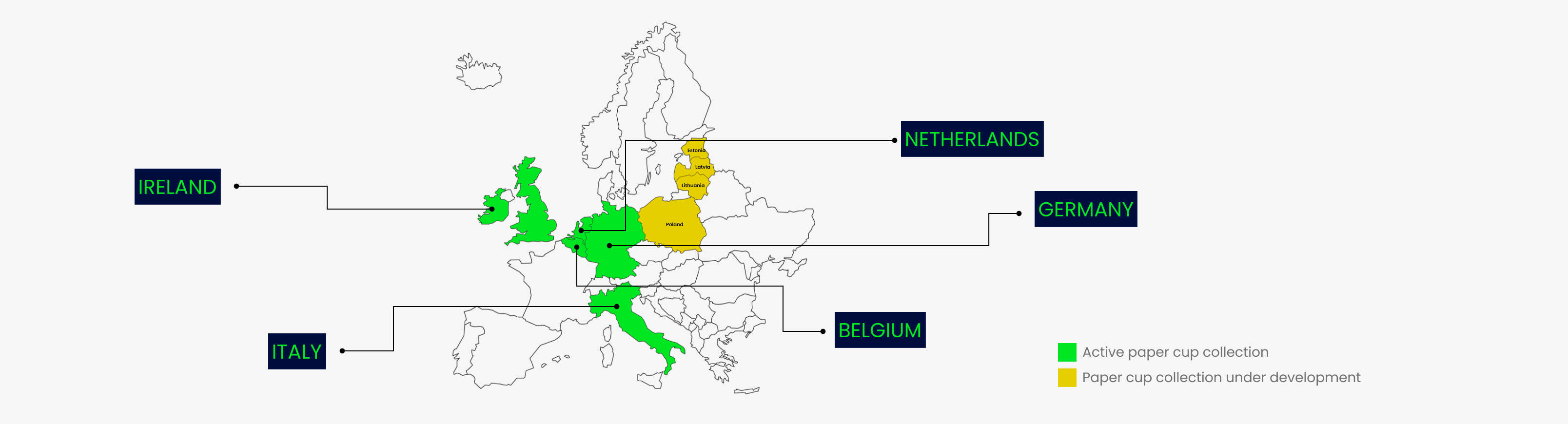

Coverage

The Cup Collective is supporting and advancing paper cup collection and recycling schemes throughout Europe. The above map details countries in which paper cup collection is currently active or under development.

Participating Collection Schemes offering a commercial paper cup and recycling solution per country can be found via the Find a Collection Partner section on the Get Involved page.

Our objective is to establish operations in all European countries, and we can accelerate this processby involving local stakeholders who express interest in participating. If your country is not currently engaged and you wish to get involved, please register your interest via the Contact Us page.

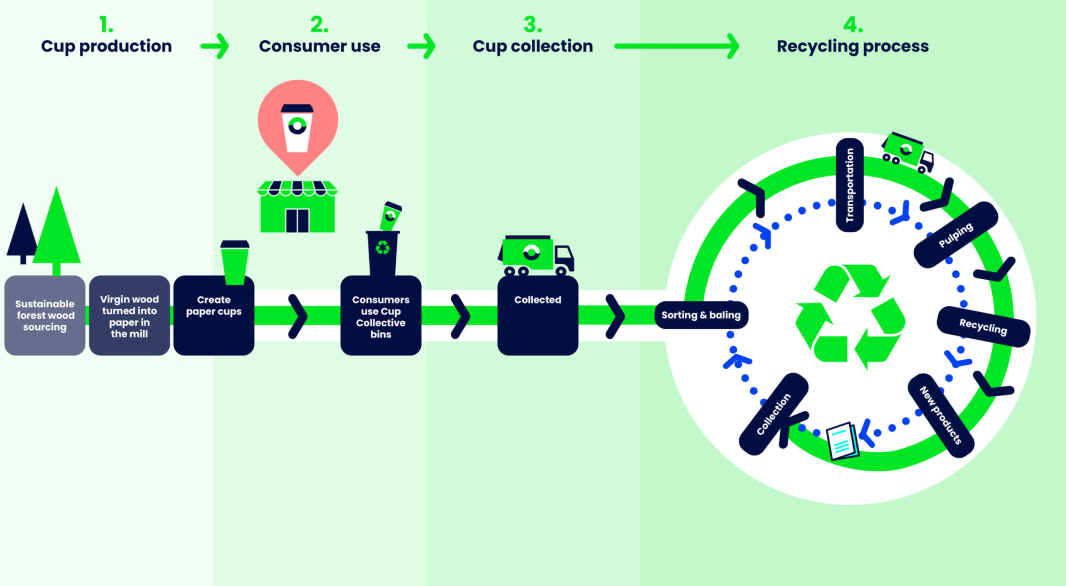

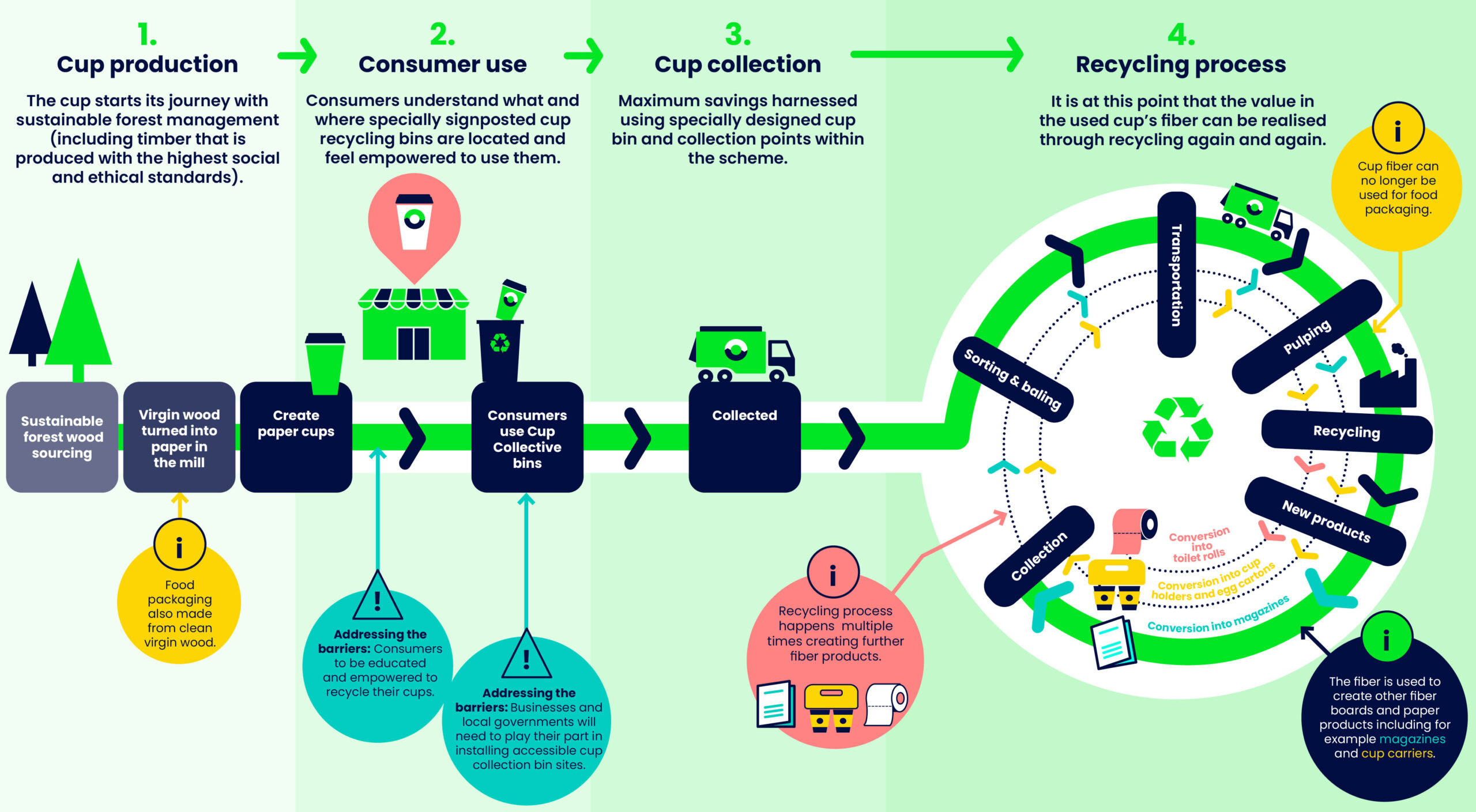

How it works

1. Cups are collected on site

Cups are required to be collected separately, which can be achieved by the use of a dedicated paper cup collection bin on site.

Source-segregated used cups are then placed into a barcoded collection sack for collection on an agreed frequency by your appointed Collection Scheme.

2. Cups are sorted and baled

Once collected, all cups are returned to a central depot for sorting, aggregation and baling. Contamination can be identified via the sack tracking system to ensure material sent for recycling meets the quality standards required by the mill(s), as well as notifying the offending site to take corrective action for future collections.

Baling cups for onward transfer means:

- - easier material handling (storage and movement)

- - transporting significantly larger volumes each journey

- - a reduction in carbon footprint and transport costs

3. Cups are sent to the recycling facility

Upon arrival at the mill, the bales of used cups will undergo further quality inspection and, once approved, will be used within the mill’s recycling process.

4. Fiber are recovered in the pulping process

Paper mills use pulpers to break down the recovered paper and cups to extract the valuable fiber contained within them. Paper cup fibers are long in length and in demand for high quality recycling applications such as magazine papers.

Due to the blades within the pulpers, the fibers will be cut shorter each time they are recycled, but even then they can be used in items such as toilet or tissue paper before they become contaminated and discarded.

5. Fibre is used to make new paper products

Recovered paper can be recycled into all manner of new paper products, they too can then be collected and recycled.

6. Paper products can be recycled after use

According to a study conducted by Graz University of Technology in Austria, fibre-based packaging material can be recycled at least 25 times without losing its mechanical or structural integrity.

Paper cups are made from virgin fiber meaning that it has never been used before and is of the highest quality. The aim is to get the fiber to be recycled as many times as possible before it can no longer be used.

Where paper cups fit in the circular story

The recycling loop: clarity on circularity

In most economies, the production process is linear; we take materials from the earth, make products from them, and eventually discard them as waste. It is a conveyor belt: make, use and dispose.

In contrast, a circular economy works on a sustainable principle of sharing, reusing, repairing and recycling the waste products back within the supply chain.

Open-loop and closed-loop recycling

Closed-loop recycling is a process where manufactured goods are recycled back into itself or a similar product e.g. glass bottles become glass bottles.

On the other hand, open-loop recycling converts secondary raw material into a new product e.g. paper cups become magazine paper, become a cup carrier and so on.

To ensure that food and beverage packaging meets the highest safety standards for consumers, used paper cups are recycled in open-loop recycling. Open-loop recycling enables efficient collection, sorting and recycling to maximize the value of secondary raw materials in circular economy.

The Cup Collective enhances the circular economy

The Cup Collective is focused on reducing the environmental impact of paper cups by creating a transparent, open-loop recycling system that integrates paper cups into the circular economy.

This maximizes the opportunity to recycle the cups many more times e.g. from cup to magazine, to cup-carrier, to cardboard, generating added value at every stage along the way by prolonging the wood fiber’s life-cycle.

Delivering systemic change through partnership

Building robust systems to solve a recycling challenge of this magnitude calls for a united will and collective action and we work with our partners through the value chain to do this together. To drive the change, we need:

- - Businesses to provide collection and recycling infrastructure, and

- - Consumers to adopt new behaviours, and

- - Researchers and scientists to develop new innovations, and

- - Policy makers to drive enabling legislation.

From manufacturing to waste collectors, governments to consumers, we all need to play our part in the recycling journey of a cup. This change will happen more quickly through collaboration and engagement with all supply chain partners.

Key Personnel

The Founding Partners

Management Team

Peter Goodwin

European Programme Manager (co-cre8)

Peter is recognised as one of the leading exponents of promoting more circular solutions. With a passion for creating a second-life from waste materials, Peter has delivered many pioneering industry projects. Most notable is the Simply Cups scheme; the UK’s first cup collection and recycling scheme that has now gone international. His practical expertise in steering and co-ordinating collaborative projects in complex multi-stakeholder environments will play a key role in the roll-out and expansion of The Cup Collective across Europe.

Wayne Basham

Commercial Operations Manager (co-cre8)

Wayne brings more than two decade’s worth of operational and commercial experience in the food service packaging and waste management sectors. His unrivalled knowledge in implementing waste management projects means that all businesses participating in The Cup Collective will have all the tools and resources they need to efficiently collect, track and recycle paper cups. Wayne will also be responsible for providing detailed reports back to those businesses, providing both transparency and opportunities for great success stories.

Peter Wildenberg

Programme Manager - Benelux (co-cre8)

Peter brings more than 30 years’ experience in both the Dutch and European paper recycling industry, as the Owner/ Director of Wildenberg Recycling and more recently following various acquisitions, as a location Manager for Veolia Paper Recycling Netherlands. Having also founded Wisselbekers in 2014 – one of the leading and most sustainable Dutch cup collection and recycling schemes, Peter has significant local expertise that will support the growth and development of The Cup Collective across the Benelux.

Huhtamaki

Huhtamaki is a key global provider of sustainable packaging solutions for consumers around the world. Our innovative products protect on-the-go and on-the-shelf food and beverages, as well as personal care products, ensuring hygiene and safety, driving accessibility and affordability, and helping prevent food waste. We embed sustainability in everything we do. We are committed to achieving carbon neutral production and designing all our products to be recyclable, compostable or reusable by 2030. Our blueloopTM sustainable packaging solutions are designed for circularity. With 100 years of history and a strong Nordic heritage we operate in 37 countries and 113 operating locations around the world. Our values Care Dare Deliver guide our decisions and help our team of over 19,000 employees make a difference where it matters. Our 2021 net sales totaled EUR 3.6 billion and our parent company, Huhtamäki Oyj, is listed on Nasdaq Helsinki Ltd.

Stora Enso

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY).

co-cre8

co-cre8 was founded with a vision that our much-needed transition to a more circular economy can only be achieved through systemic thinking.

From our many years’ experience designing and implementing recycling programmes, including the world-leading Simply Cups cup recycling scheme, we now have a unique understanding of how to both maintain consumer engagement and increase material collected.

Key Personnel

The Founding Partners

Management Team